ABOUT US

NG Tooling Solutions is a company dedicated to the design and manufacture of solid carbide cutting tools of the highest quality. Among our main customers are diverse industries such as: aerospace, energy, automotive, medical, electronics, molds, among others.

In order to meet the general and particular needs of the manufacturing industry, NG TOOL was founded. A brand with a wide range of products whose mission is to provide work solutions for industries that demand maximum performance in the production process.

We have cutting tools such as milling cutters, drills and special cutters of high complexity as a result of the study of the needs of each company.

Using the experience and skill of our qualified engineers and our state-of-the-art CNC production equipment, we are able to design and manufacture cutting tools for the most demanding applications. We are committed to working hand in hand to provide you with the product that will help you achieve your production goals.

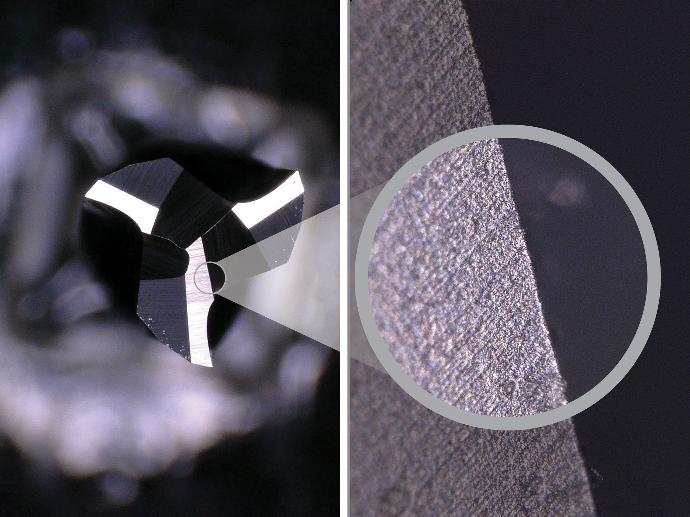

HIGH-TECH

Our high-tech equipment allows us to manufacture tools of higher precision and complexity.

EQUIPMENT

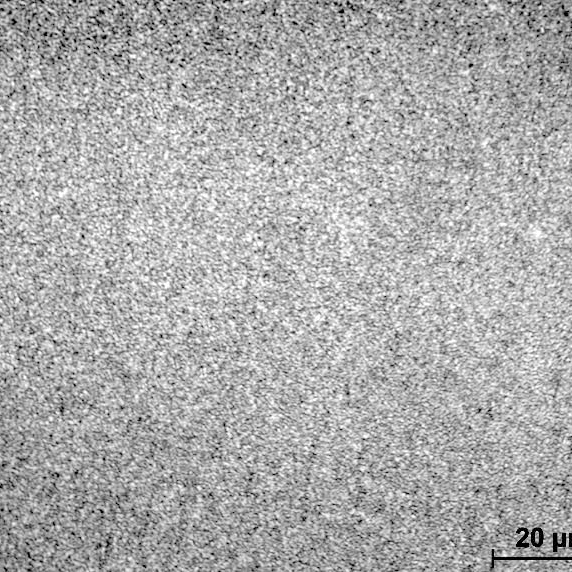

We have specialized equipment for the inspection of our products, guaranteeing that our tools are within optimum tolerances.

HIGH-PERFORMANCE

Our thorough tooling review process allows us to see in detail that high quality standards are met.

OUR CARBIDES

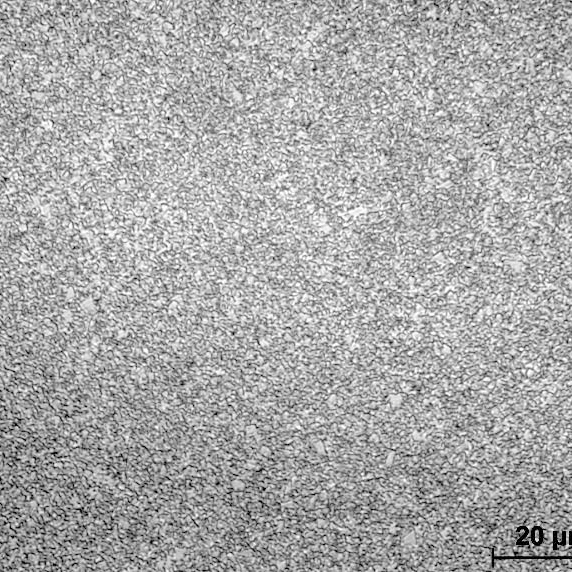

NG-CARB-01

Submicron grain size carbide. Due to its great versatility it can be used for milling, drilling and reaming of ferrous, non-ferrous and refractory materials.

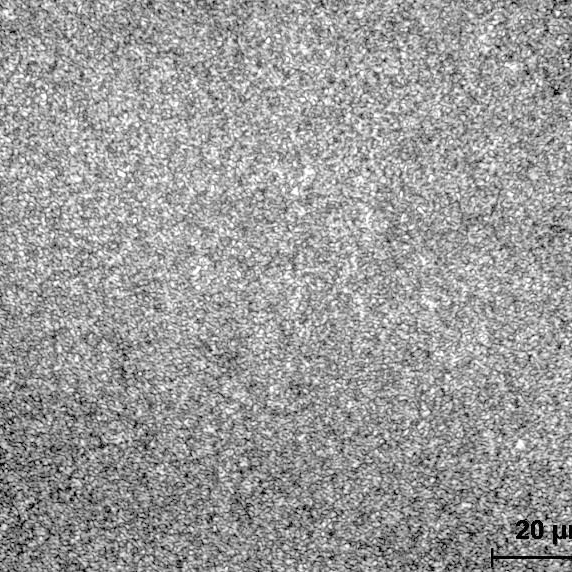

NG-CARB-03

Ultra-fine grain size carbide. Thanks to its high percentage of cobalt, it increases its impact resistance. Ideal for roughing and high demanding applications in non-ferrous materials.

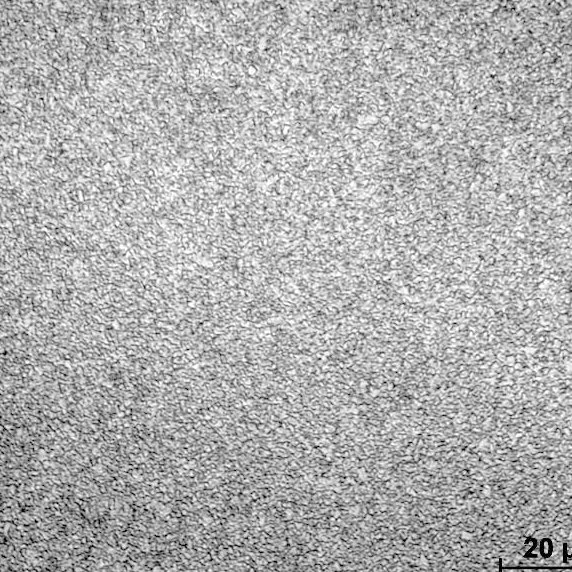

NG-CARB-02

Ultra-fine grain size carbide.

Among its characteristics are its greater resistance to shocks and wear.

NG-CARB-04

Ultra-fine grain size carbide. Optimal for machining hardened materials from 50 to 65 HRC. Prepared for wear resistance against materials such as high speed steel, hardened steel and composite materials.

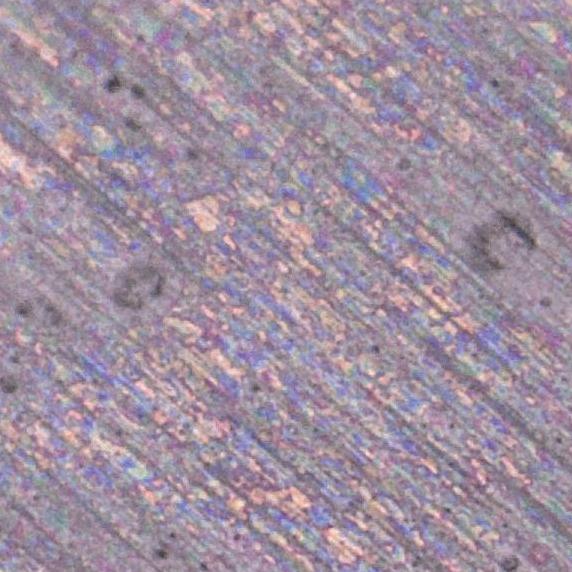

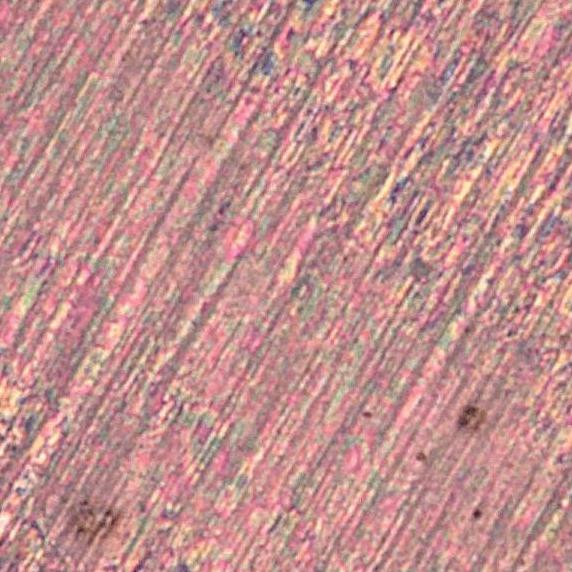

OUR COATINGS

CRONALUM

It is a general purpose coating ideal for iron-based materials. It provides tools with exceptional resistance to wear and high temperatures. Higher cutting speeds can be achieved with this coating resulting in a direct increase in productivity.

TITRALUM

This coating, even at high temperatures, provides superior abrasive wear resistance and increased tool ductility. Thanks to its enormous performance, it is ideal for the most demanding machining operations.